Manufacturer of Pipe Fittings In Mumbai | Maha Bhairav Stainless Steel

Manufacturer of Pipe Fittings In Mumbai | Maha Bhairav Stainless Steel

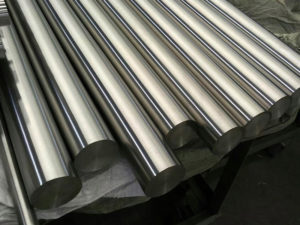

Stainless Steel Pipe Types

For Manufacturer of Pipe Fittings In Mumbai Contact Maha Bhairav Stainless Steel

he most common pipe screens are made of metal mesh, cut into small circles, which can be bent to fit the inside of your bowl. The idea is that while smoke and fine ashfall through, large chunks are held in place.

Using a pipe screen keeps your pipe a cleaner, but more importantly, stops large clumps of ash from being pull through to your mouth.

First, practice handling the gun without actually welding. Rest its barrel in one hand, and support that hand on the table. The other hand operates the gun’s trigger.

Stand in a comfortable position and move the gun steadily over the work surface. Adjust your posture and gun movement so that they feel natural.

Metal inert gas welding (MIG) is also known as wire welding or gas metal arc welding (GMAW). MIG welding is usually the starting point for novice welders.

The process uses a welding wire, which is the filler rod, as an electrode; the wire is used to complete an electric circuit that passes through the two objects being welded together.

Pulling the wire back slightly creates an arc of electricity that is super-hot, and this arc melts the wire and partially melts the two metals being joined. The place where they all melt mixes together and cools, forming a solid joint with a bead running along the seam.

Carbon steel is much more durable and stronger than other varieties of steel, which makes it suitable for making pipe fittings.

Also known as plain-carbon steel, carbon steel is a malleable and iron-based metal, containing mainly carbon and small amounts of manganese and other elements.

Twist on a pipe or fitting by hand. If it does not turn easily, the joint is not straight and the threads are crossed. Back up and try again. Then firmly tighten each pipe or fitting using a 14-inch pipe wrench. You may need a second wrench to hold the adjacent piece steady.

Metal pipe screens come in different sizes, usually ranging from 0.5” to 1”. Bigger bowls need bigger screens. Since metal screens are so malleable.

You must simply press the mesh disc into the pipe until it fits flush with the bottom of the bowl. Be sure that the screen covers the hole. Metal and wood pipes typically have holes in the side, while glass bowls have holes on the bottom.

Next, grind or file a slight bevel along the edges you’re welding. This ensures the weld penetrates as deeply as possible and countersinks it so you can grind it flush. Don’t overdo it or you’ll burn through the metal when you weld.

Again there are some butt-weld carbon fittings, which feature beveled edges and form a channel of lesser depth for the bead of weld that fixes the piece together.

Butt-weld fittings are mainly used to join sections of pipe where permanent and welded connections are required. Elbows, reducers, tees, etc are made of butt-weld steel fittings.

During installation, it’s important to make sure the pipe isn’t fit too loosely or too tightly. A loose pipe will sag or bend, which can lead to wear and broken pieces.

The recommended spacing between the pipe and clamp often depends on the pipe’s weight. Also, it’s smart to remember piping can expand and contract as it heats up or cools down.

Tack the pieces together at a couple of places along each joint. Check again for square corners; if anything shifts and puts the assembly out of square, grind away the tack weld, reposition the parts, and try again.

Hot cracking is caused by low melting materials such as metallic compounds of sulfur and phosphorous which tend to penetrate grain boundaries.

Now you know how to use pipe screens and maintain them for the best performance. You ordered some quality glass pipe screens from BadassGlass, too, but in the meantime, you still need a screen! It’s time to get crafty with some pipe screen solutions.

When you’re suspending piping, it can be nerve-wracking. After all, if fasteners fail, structures could come crashing down.

A key way to avoid failed fittings is to make sure you’re precise when you tighten the nuts to the bolts. Too tight, and you could strip them. Too loose, and clamps could come undone when pipes vibrate.

Once the tee-fitting for the new line is installed, add a nipple and slip on the nut for the union, checking that the threads are toward the joint. Apply tape and install half of the union. Set the second half of the union in place and measure for the final section of the pipe.

Fittings made of carbon steel are used in pipe systems that carry liquids or gases, such as oil, water, natural gas, or steam.

Apart from that, carbon steel fittings are highly demanded in construction and maintenance activity in the residential construction, commercial construction, electric power generation, petroleum refining, shipbuilding, and other industrial-use sectors.

In highly-specific aircraft applications, chromium and nickel type stainless steel is used because of their heat and corrosion-resistance.

Found in applications that require high-strength, stainless steel aircraft tubing can be work-hardened or welded, although work-hardened pieces shouldn’t be used with some kinds of corrosive substances. Low-carbon types of stainless steel are a common choice for welded parts.