Stainless Steel Forge Round Bar In Mumbai | Maha Bhairav Stainless Steel

Stainless Steel Forge Round Bar In Mumbai | Maha Bhairav Stainless Steel

Tips For Stainless Round Bar

For Stainless Steel Forge Round Bar In Mumbai Contact Maha Bhairav Stainless Steel

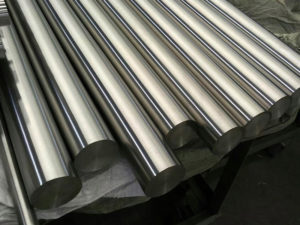

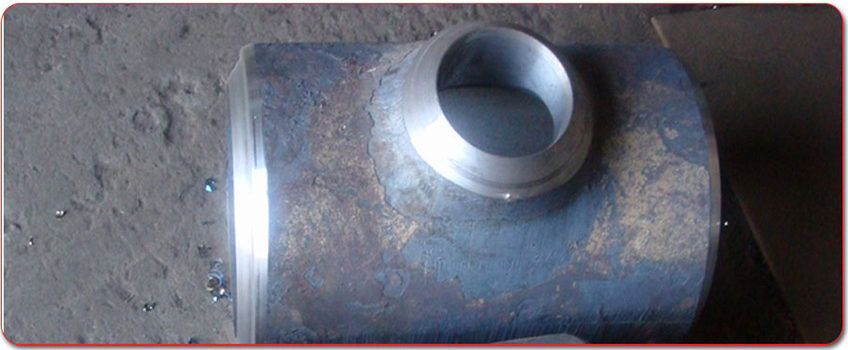

When you’re looking for an extensive variety of high-quality bar stock. furnishes a full line of stainless steel bar stock in rounds, squares, and flats. The bar is ordinarily ordered by its nominal diameter. The sizing chart shows the nominal size and provides convenient weight data. However, for centerless grinding purposes when tolerances are tight, bar stock is generally ordered “oversize” to allow for sufficient material removal.

The most common and hence most frequently machined stainless steels are the austenitic types, such as grades 304 (1.4301) and 316 (1.4401). These are characterized by their high work hardening rates and poor chip breaking properties during machining. This article covers the important issues that influence the successful machining of these steels.

Anyway, 304 is an austenitic stainless steel, so it shouldn’t lose any strength from the heating. Bending it could work-harden it, and strengthen it substantially; if it didn’t break from the tight radius of the bend.

Stainless steel bar offers plenty of unique benefits for numerous industries and applications. The benefits of stainless steel bars include material longevity, corrosion resistance, attractive appearance, ease of fabrication, impact resistance, and long term value. Stainless steel is one of the most widely used metals in the modern construction world.

Either tungsten or molybdenum HSS can be used. These are particularly useful in machining operations involving the high feed and low-speed machining operations where there are variable cutting edge stresses induced from complex tool shapes.

The tungsten types (eg T15) can be useful for their good abrasion resistance and red hardness. The molybdenum HSS is more widely used, M42 being useful for applications such as milling cutters where a good combination of hardness and strength are required at lower cutting speeds. M42 has better hardness than grades like the more common M2, but may not be as tough, however.

You do want to avoid holding it for any length of time at high temperatures, or you’ll compromise the corrosion resistance of the alloy. You’ll get some scaling on the outside regardless, but I doubt this will matter. It’ll polish away with a little work.

Where possible the tool faces should incorporate chip curlers or breakers as austenitic stainless steels are prone to forming long spiraling turnings that can easily wrap around the tool and tool post. These can easily become entangled around the tooling and are difficult and time-consuming to remove. In extreme cases, the tool can become jammed by entangled turnings.

Not sure which bar stock choice is right for your unique needs? Simply contact Maha Bhairav Stainless Steel, and one of our skilled specialists will be happy to help you!