Stainless Steel Pipe Supplier In Mumbai | Maha Bhairav Stainless Steel

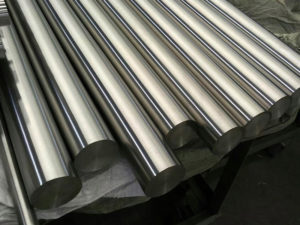

Stainless Steel Pipe Supplier In Mumbai | Maha Bhairav Stainless Steel

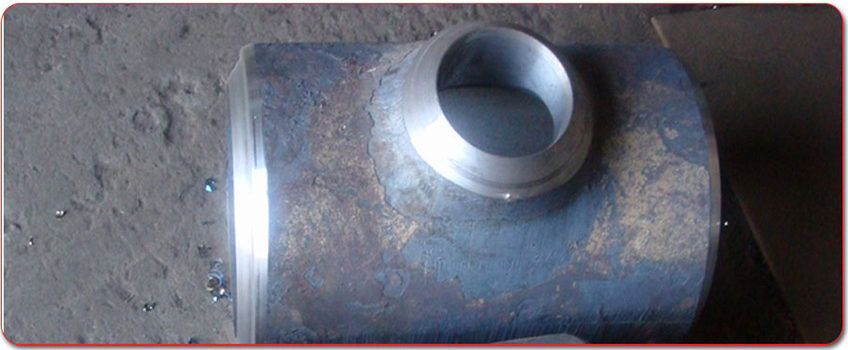

ASTM A234 Wpb, ASTM A234 Gr Wpb, ASTM A234 Fittings Manufacturers in India, Alloy Steel Pipe Fittings Manufacturers,

Call: +91-022-66109829 | Send Mail: mahabhairavstainless@gmail.com

An ISO 9001:2008 Certified Company, Maha Bhairav Stainless Steel is one of the leading Alloy Steel Pipe Fittings Manufacturers, engaged in the manufacture and distribution of ASTM A234 WP11 Elbow, ASTM A234 WP11 Tee suppliers in India, ASTM A234 WP11 Reducer.

Manufacturer of Stainless Steel Flanges in India, AISI 304, 304L, 316L ANSI B16.5, DIN Standard, Table D, E , ASTM A182 Stainless Steel Flanges Manufacturer in India

his specification covers forged or rolled alloy and stainless steel pipe flanges, forged fittings, and valves and parts for high-temperature service. After hot working, forgings shall be cooled to a specific temperature prior to heat treatment, which shall be performed in accordance with certain requirements such as heat treatment type, austenitizing/solution temperature, cooling media, and quenching. The materials shall conform to the required chemical composition for carbon, manganese, phosphorus, silicon, nickel, chromium, molybdenum, columbium, titanium. The material shall conform to the requirements as to mechanical properties for the grade ordered such as tensile strength, yield strength, elongation, Brinell hardness. All H grades and grade F 63 shall be tested for average grain size.