Stainless Steel Round Bar In Mumbai | Maha Bhairav Stainless Steel

Stainless Steel Round Bar In Mumbai | Maha Bhairav Stainless Steel

Ways of Finding the Best Stainless-Steel Pipe

For Stainless Steel Round Bar In Mumbai Contact Maha Bhairav Stainless Steel

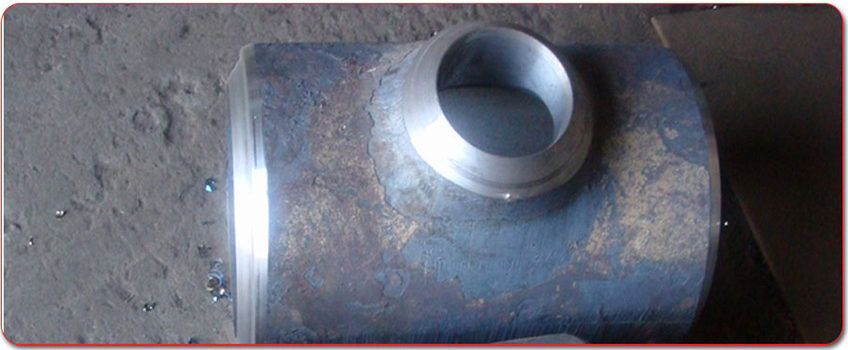

The stainless-steel fittings and pipes are integral to the operations in industrial settings. They can control and manipulate the flow of gases and fluids through the pipes.

Most importantly, these components ensure the safety and enhanced productivity of your existing equipment. Hence, it is important to choose the right type of fittings depending on the individual requirements of your applications.

Stainless steel is known fundamentally for its corrosion resistance, is utilized in a wide assortment of applications. The diverse range of grades enables it to suit different applications across many different industries. However, having so many grades requires the know-how to select the appropriate one for the job.

There are many different grades of stainless steel. The two commonly used grades are 304 and 316, with 316 being more corrosion resistant than. The rule of thumb is that if the fastener is in a corrosive environment is preferable, particularly if the fastener is to be seen, as 316 is less likely to ‘tea-stain’ or develop a brown discoloration.

Do you have the time and manpower to continually monitor and fix leaks that can occur with materials that are more susceptible to rusting at joints and leaking?

They are probably the most traditional plumbing pipe used due to their extensive duration and reliability. They provide superior corrosion resistance, great material to be used for hot and cold water, and it can be managed easily.

However, the most important factor to consider before using copper piping is that it needs to be soldered together and it might require additional fittings. Not everyone is good at soldering copper pipes, so talk to a plumber.

Welding stainless steel is very different than welding carbon steel and can lead to problems such as intergranular corrosion, hot cracking, and stress corrosion cracking.

The most weldable stainless steels are typically in the austenitic group. When welding austenitic stainless steel, grades should be used. Grade has lower carbon while has niobium stabilizers added to it which helps to deter intergranular corrosion.

Ferritic stainless steels are also readily weldable, as are Duplex stainless steels. Martensitic stainless are generally not suitable for welding,

However, some martensitic stainless steel grades with lower amounts of carbon can be welded. With precipitation hardened stainless steels, care should be taken to ensure that the original mechanical properties are not compromised during the welding process.

If machining is required, special considerations must be accounted for when working with stainless steel. Most grades of stainless steel can be machined, however, stainless steel is very susceptible to work hardening. The machining process must be optimized to work at a rate that helps alleviate this issue, and the tools used for machining must also be kept in good working condition.