Stainless Steel Forge Round Bar In Mumbai | Maha Bhairav Stainless Steel

Stainless Steel Forge Round Bar In Mumbai | Maha Bhairav Stainless Steel

Tips For Stainless Steel Round Bar

For Stainless Steel Forge Round Bar In Mumbai Contact Maha Bhairav Stainless Steel

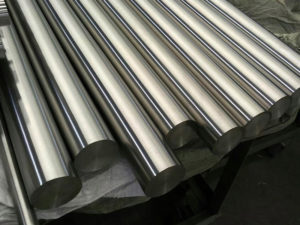

Stainless steel round bar besides having the characteristics of corrosion resistance has been developed over time to encapsulate end-user applications.

For example, Improved Machining (IM) grades have been developed to enhance machining of the steel into components, grades for hardness by responding to heat treatment and grades with high corrosion qualities by adding additional elements to give it the characteristics desired.

Round bars are made with high-quality material, that’s the major reason they’re so popular with our business.You can also find that square bars are provided in a wide variety of casting materials. Whatever you take a stainless steel bar for, we are sure to have the perfect one to meet your special requirements.

Stainless steel round bar consists of stainless steel including chromium and it contains chromium it is extremely resistant to corrosion.

It’s the most common item, so we always stock just about all steel grades to meet market demand. Whether you’re in need of a small quantity of stainless steel round bar or a big amount of tread-bright aluminum, we can help!

Stainless Steel Round Bar can be headed, stamped, upset, and drawn even though it has high work hardening rate, Annealing of 430 Steel Round Bars is performed after cold working in order to reduce internal stress.

When handling steel material, appropriate Personal Protective Equipment such as hard hats, steel-toed boots, and gloves must be worn.

Cranes, forklifts, or hoists used to handle steel must be load-rated for the job. Equipment limits and load charts must be prominently displayed.

The storage of steel material presents many potential hazards. The steel may roll, slip, slide, or fall over if not properly restrained while stored.

Shelves or racking may collapse if the system is not suitably designed for the purpose. Racking or shelving systems must be cross-braced to prevent collapse.

All the professionals involved in each operation must be properly qualified for the task and know all the information regarding the project: weights, cargo, transportation, etc. This is the only way to plan all the work with all guarantees.

Coil steel is one of many versatile forms of steel and comes in a great variety of sizes and weights; some may weigh up to 15 tons.

There is a hazard of violent whipping movement if the coil is allowed to uncoil without restraint. Coiled steel rolls easily, even in high weights. Therefore, there is great potential for serious injury or even fatal accidents if coil steel is not handled and stored properly.